Our mission is to fill The Barrel with

Real American moonshine, made in Spain, in French oak barrels, on a Russian still, via a English parrot.....Why not its nice

|

|

|

![]()

11th Feb 2018

Found the barrel on Polop flea market Spain,

I think it`s a French oak sherry barrel use to age wine,

I was more than happy with the asking price of €40 with the stand lucky she just fits on the bike...

I almost left the stand on the car park... glad i did not...

|

|

Removed 2 or 3 Litres of wine then filled with 15.5 Litres of water, just to rinse, and out popped oak char.. i dried and added 0.1 grams to 10mls of 80% spirit... 3 days later.

![]()

The Proofing Parrot MK1 came from the UK

|

|

|

15th Feb 2018

Shopping Take 2

10Kg split corn

5Kg barley for malting part 2

12th Feb 2018

The Monster Mash

46.23 US Gallon --174.999 Litres

Corn 33.551Kg... needed 8.5Kg

Malted barley 5.242Kg... needed 0.242Kg

Sugar 41.939Kg... needed 10Kg

70 Litres of boiling water... 105 Litres of cold water

7 packs of turbo 48 yeast... needed 2 packs

Here were we started thanks to Bryan from home distillers

For a 10 US gallon batch

16 lbs of flaked or cracked corn. I prefer cracked corn as it's less mess. 40 oz of 2 row malted barley, ground.

Bring 4 gallon of water to a boil then turn off heat and add corn.

Add 10 lbs of sugar. Stir for around 5 minutes. Cover and let cool to 155°F then add the barley. Stir another 5 minutes. Cover and let stand for 90 minutes.

Then add the rest of your water. At below 90°F pitch your yeast. Wait 10 minutes then stir gently to incorporate the yeast.

7 to 10 days it will be ready to run.

For a 1 gallon batch (3.78541L)

1.6 lbs corn (0.725748Kg)

4 oz malted barley (0.113398Kg)

1lb to 2lb sugar (0.453592Kg to 0.907184Kg)

0.4 gallon of water 1.51416 ml

+.6gal

![]()

15th Feb 2018

The Monster Mash MK2

***with 5Kg of barley malting and no way to know how much I will have when finished, I may have to change things a little***

175 Litres max 220 Litres

Corn 33.551 Kg ... 35Kg now in stock

***Malted barley 5.242 Kg ... 5Kg malting with 5Kg in stock***

Sugar 42Kg ... 50Kg now in stock

7 packs of turbo 48 yeast... Need 2 packs

70 Litres of boiling water .. 105 Litres of cold water

Will have to boil in 4 batches of 17.5L maybe (3 at 23.33 L)

18th Feb 2018

The monster mash MK3 ready to go

***4.908Kg of malted barley from 5Kg of barley***

For a 164 Litre batch (43.3 gallons)

31.424Kg cracked corn. (3 X 11.16Kg)

4.908 KG of malted barley from 5kg of barley (3 x 1.66Kg)

6 packs of turbo 48 yeast

Bring 66L of water to a boil then turn off heat (3 x 22 Liters)

Add corn and 39.300kg of sugar. (3 x 13.1Kg)

Stir for around 5 minutes.

Cover and let cool to 68.33°C (63.5°C) then add the barley. (3 x 1.636Kg)

Stir another 5 minutes. Cover and let stand for 90 minutes.

Then add the rest of your water. 98 Litres

At below 26.66°C pitch your yeast. Wait 10 minutes then stir gently to incorporate the yeast.

7 to 10 days it will be ready to run.

19th Feb 2018

Mash day started at 7am i sat down at 7.01pm boiling of the water was this 1st hiccup the cooker in my house was just not up to the job the gas ring from the still saved the day.

|

|

|

|

The same I had to do 6 batches when i needed more hot water to get the temp back up to 63.5°C i just about made it...

|

|

|

|

|

I added cold water but the temp was 57.5°C, i hooked the cooling coil to the house water supply that did the trick.

The yeast when in at 24°C, I hooked the cooler and heater up to the controller set to 22°C and the cooler kicked in was at 23.4°C and cooling at 7.01pm air stone set to low, I rapped the monster up for the night...

![]()

Malting the barley

We could not get malted barley so we need to DIY it

|

|

|

|

4 trays with holes drilled in the top, fill two trays with 1/3 with barley

|

|

|

Fill 2/3 with warm water. Remove everything from the surface

Replace the water every 4 to 8 hours.

Cover and wait 1 to 2 days until the barley splits

When split keep covered and turn every 2 to 4 hour spray with water.

Once the barley has split turn and spray until the shoot is the same size as the seed difficult to see until you see it.

|

|

|

|

|

17th Feb 2018

Two schools of though, one says keep under water for 1 to 2 days and the other says flood and then drain... let do both and see what happens and as in turned out the flood and drain was ready to start drying the morning of the 17th....

|

|

|

18th Feb 2018

Rain stops play or does it ..... oven set at 90°C with door open.

|

|

Remove all the root and then grind 4.908Kg of malted barley, done.

|

|

|

|

I started with 5Kg finished with 4.908Kg of malted barley

Bring 70 Litres of water to a boil

70 Litres of Boiling water .. 105 Litres of cold water

I will have to boil in 4 batches of 17.5 Litres maybe (3 at 23.33L)

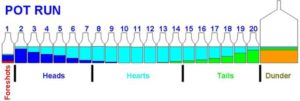

***Making the cuts***

The barrel holds 15.5 Litres but we are going to need 2 to 3 times that if we want to fill it with hearts....

175 Litres @ 15% will distill to 26.25 Litres ...... 20% to 35L @100%

175 Litres @ 15% 1 Litres

1.5L Foreshots + 5L heads + 15.5L hearts + 5L Tails = 26.5 Litres

20% to 35 Litres @100%

2.5L foreshots + 8.5L heads + 15.5L hearts + 8.5L Tails = 35 Litres

1st March 2018

3.6 Litres sort....of target proof of 75% would it be ok to barrel at 72% 144 us 108 uk ???

Day 9 mash its still going now @ 14.35%

I took 1200ml and run it via lab still got 325ml at 53%

that's work out around 14.35% ABV in the mash now

I was working on 15.5 Litres of hearts at 75% to fill the barrel 11.625L at 100% with head and tails that's around 35 Litres total

175L mash @ 14.35% would give me 25.1125L @ 100% or 31.39 @ 75%

I am 3.6L sort......of target proof of 75%..

I Love it when a plan comes together

3rd March 2018

15.5L of hearts at 75% to fill the barrel 11.625L at 100% with head and tails that's around 35L total

started the striping runs 2L @ 55% ABV from every 8 Litres of wash works out 13.75% ABV at this rate i will get 43.75L @ 55% from 175L wash

simple math round up to 44L and down to 50% or 22L @ 100% i will be 3.11L sort to fill at @75% ABV.... 150° USA proof ...112.5° UK proof

I am told 105 USA proof 52.5% ABV 78.75 UK proof will be fine to barrel .... but i would like to go for 63.5%ABV

a long way to go but if everything goes well we should make this with pure hearts...... may be a little more

7.41pm just started the 5th run this will be the last run today

5th March 2018

7.25pm the last striping run goes in the still that makes 17 runs in the last 3 days... 35.5 L @ 53 to 58% = ABV 19.52L @ 100% ABV or 26.84L 63.5% ABV

Next wind free day I start the stripping runs 35.5L that's another 6 slow runs i know that's would be 48L but I may need to do another run with the heads and tails all hearts even if i have to proof down to get that 15.5L

Did i say i m going to need a bigger still and a boiler.....

6th March 2018

Ended with 37L proofed down to 45% and started the spirit run 4 runs cutting deep in to the heart removing 200ml for every run as foreshots and 1.5L of heads and about the same for tails....heads and tails put with 5L of the 1st distill proofed down to 45% made 18L ... 2 more runs of 9 L the max for my little 12L still....

8th March 2018

The last 2 runs give up a little more hearts the the 1st 4 runs

6.00pm the still is now runing the last of the tails

Just in time the UPS man turned up with new hydrometer.

Jar 1 ... 3L @ 88%

Jar 2 ... 3L @ 89%

Jar 3 ... 3L @ 90%

Jar 4 ... 3L @ 90%

Jar 5 ... 2L @ 90%

Total 14L @ 89.4%

![]()

Now for the proofing

Cask strength (also known as barrel proof) is a term used in whisky-making to describe the level of alcohol-by-volume (abv) strength that is used for a whisky during its storage in a cask for maturation – typically in the range of 60–65% abv.[

63.1 ABV / 94. UK proof / 126.2 US proof

58.4 ABV / 87.6 UK proof / 116.8 US proof..........Wild Turkey

Cask strength is not the highest proof that a whisky can be. Still-strength whisky is a higher proof, which comes out of the still at about 70% ABV. Some distillers bring down the proof by adding water to the whisky prior to casking it. Further aging of the whisky in a cask will reduce the proof.[

The plan was for 75% ABV / 112.5 UK proof / 150.0 US proof so thats what we will proof down to and barrel 16.6L total @ 75% ABV.... not sure what happened but i could only get 13.3L in the barrel i must have made a misstake right at the start so I have have a little over 3L left over

Click here to see the dilution calculator

9.15pm My 1st barrel is filled my son logon is allmost 5 months old I think I will name after him

Logon`s Run

Barrelled on the 8th day of march 2018

![]()

The Barrel mk2 - Real American moonshine, made in Spain, in French oak barrels, on a Russian still, via a English parrot polish hemp

![]()

????The monster mash mk3 back wash 1/3... 58.33 Litres ???? bricks 4

31.424 Kg cracked corn. (3 X 11.16Kg)

4.908 Kg of malted barley from 5Kg of barley (3 x 1.66Kg)

6 packs of turbo 48 yeast

Bring 66L of water to a boil then turn off heat (3 x 22 Liters)

Add corn and 39.300kg of sugar. (3 x 13.1Kg)

Stir for around 5 minutes.

Cover and let cool to 68.33°C (63.5°C) then add the barley. (3 x 1.636Kg)

Stir another 5 minutes. Cover and let stand for 90 minutes.

Then add the rest of your water. 98 Litres

At below 26.66°C pitch your yeast. Wait 10 minutes then stir gently to incorporate the yeast.

Run for 12 days

![]()

?????? Making it up as I go ??????

Only adding water, sugars, glucoamylase and alpha amylase to old mash

Mash started Brix 8.25° adding back wash at 30%

Removed 60L to corn from barrel

Mixed in the grain with water .....

Brix 2.25°

Added glucoamylase at 55-60°C pH of 4.0 to 5.0.@ 2g per 25L

Brix 4.25°

Added alpha amylase at 45 to 50°C and a pH of 4.5 to 5.5 @ 2g per 25L

Let stand for 90 minutes

Brix 7.00°

Added sugar 30Kg to back wash

Brix 15.5°

Cooled to 28.0°C

Added to the corn and yeast that was left in the barrel

24 hours later - Brix 10°

24 hours later - Brix 5°

Added 1Kg of Caine sugar and 2Kg of sugar

Brix 7.25°

4 hour later added another 2Kg of sugar

Brix 10.25°

24 hours later

Brix 7.5°

12 hours later

Brix 6.75°

24 hours later

Brix 7 .00°

![]()

The Mulit Grain Mash MK1

175 Litres Max 220 Litres

Corn 33.551Kg … 35Kg now in stock €10 Sweet

Hemp Seed 5Kg .... 25Kg now in stock 1Kg (Malting) Nutty Coffee

Muntons Crystal 150 Malt ... 10Kg now in stock €14 - Nutty

Muntons Roast Barley Malt ... 10Kg now in stock €14 - Chocolate Coffee

Sugar 30Kg … 48Kg now in stock €0.67 per Kg - €20.10

2 packs of 1410 Gozdawa Turbo Yeast 5 packs in stock now Mega Pack 100L €5 per pack €10

70 Litres of boiling water .. 105 Litres of cold water

25Kg now in stock

1Kg (Malting)

Boiling Points of various compounds

Acetaldehyde 20.8°C

Butylamine 46°C

Propionaldehyde 46°C

Propyl Amine 48°C

Ethyl Formate 54°C

Ethyl Acetate 77.1°C

1-propaanol 97°C - Tails

Butanol or butyl alchol 118°C - Smells like bannana

Acetic acid 118.1°C

Amyl (Isobtyl Carinol) 131.6°C - Tails

Furfural 161.7°C