A rotary evaporator is a device used for the efficient and gentle removal of solvents from extract/ solvent mixture by evaporation. Since the sample is under a high vacuum (low pressure) the evaporator system the boiling points of all the compounds is reduced. Once consequence of this is that the majority of the oxygen in the reaction is reduced and oxidative breakdown of the components is reduced.

One of the main advantages or using this system is that the solvents are condensed back into liquid form and not exposing the immediate environment. The collected solvent then can be stored and used for cleaning glassware and other equipment, vastly reducing the amount of solvent needed and cost. In some cases the collected solvent can be further processed via fractioning the isolate remaining components of the extract that have made it through the evaporation stage.

|

The main components of a rotary evaporator are: A motor unit that rotates the evaporation flask containing the extract solvent mixture. A vapor duct that is the axis for sample rotation, and is a vacuum-tight conduit for the vapor being drawn off the extract/solvent mixture. A vacuum system, to substantially reduce the pressure within the evaporator system. A heated fluid bath to heat the mixture. A condenser with a coil passing coolant, usually water . A condensate-collecting flask at the bottom of the condenser, to catch the distilling solvent after it re-condenses. A mechanical or motorized mechanism to quickly lift the evaporation flask from the heating bath. |

![]()

Additional Flasks

When using a rotary evaporator the maximum amount of liquid in the evaporating flask is half its volume or less. As an example if you have a 1 litre evaporation flask the maximum amount of fluid you can evaporate safely is 500ml.

The receiving flask must be able to hold evaporated liquid. as an example if the evaporation flask was 1.5 Litre, you would need a 2 Litre receiving flask.

![]()

Temperatures

Choosing the bath and condenser temperature (20-40-60 Rule)

There is a relationship between the heating bath temperature and the evaporation rate. The more energy applied to the evaporation side and the amount of energy removed from the vapors on the condensation side, the more efficient is the distillation.

In the 20-40-60 Rule the recommended water bath temperature is 60°C. This minimizes evaporation from the bath, reduces the risk of burns, and minimizes the loss of heat energy into the lab environment.

The bath temperature should be 20°C higher than the vapor pressure temperature of the solvent. In this example, a vacuum pressure is chosen to produce a vapor pressure temperature is 40°C.

The condenser temperature should be 20°C lower than the vapor pressure temperature of the solvent. In 20-40-60 rule , the vapor pressure temperature is 40°C, so the condenser temperature should be 20°C. By following these simple guidelines, costs can be reduced and results can be optimized.

|

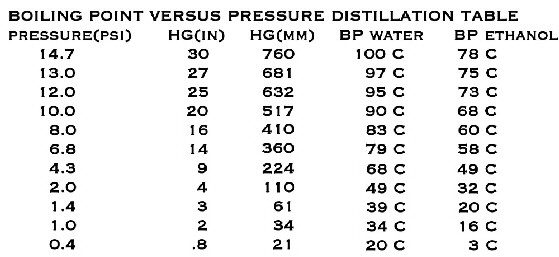

Now we consider vacuum into the equations, say we have a pump that goes down to 2 PSI which is 137 millibar, the boiling point of ethanol is 32°C under this vacuum.

Using the 20-40-60 rule , we substitute the 40 with 32°C, which would give us a water bath temperature of 52°C (32+20) and a condenser temperature of 12°C (32 - 20). |

![]()

Recirculating chiller or Mains water

The condenser has a coil with coolant circulating through it, the cheapest method of doing this is to connect your mains water supply through piping.

Another method is to use a water pump to circulate ice/water mix from a sink or suitable container.

One of the best methods is to use a recirculating chiller, although expensive. A recirculating chiller is basically a water/fluid bath that is chilled with a refrigeration unit. The temperature of the chiller can be set to just above 0°c when using water, or to around -10°C if you are using antifreeze (Propylene glycol). This method allows you to have a more efficient and stable evaporation.

![]()

Vacuum Pump

When choosing a vacuum pump, If you choose a vacuum pump with a very low pressure (high vacuum) you may need to get a vacuum regulator to adjust the vacuum to a level that is extract/solvent mixture.

Most of the vacuum pumps on ebay that have a very low pressure (high vacuum) but from experience get hot very quickly, and have oil for lubrication and cooling, which can get contaminated by any vapor that makes it past the cold finger.

The best kind of vacuum pump to use would be a diaphragm vacuum pump. Preferably a chemically resistant diaphragm pump would be the best choice but they are quite expensive.

From the information we have found so far we need a pump that goes down to at least 2 PSI which is 137 millibar or 103 Torr.

![]()

Vacuum regulator and controllers

Vacuum regulators work by venting air into the system so lowering the vacuum (increasing the pressure) which means your vacuum pump is constantly on. If you are going to use this method you are best using a pump that will not overheat, an example would be a pump made by KNF. As previously said it is best that you look for a diaphragm pump which do not have oil that can be contaminated by any solvents still remaining in the air being removed from the system.

Vacuum controllers work by using a combination of solenoid valves, one to allow air from the outside to enter the vacuum system, and another to turn your vacuum pump on and off. These can be quite expensive but are a much better way to stabilize the vacuum within the system.

![]()

Cold Traps

|

A cold trap or cold finger is a piece of equipment that goes between the buchner funnel and the vacuum pump. Its purpose is to condense any vapor that is evacuated from the buchner flask, which collects at the bottom.

If you are not using a chemical resistant vacuum pump, any vapors may enter the pump, by using the cold trap you are reducing the chance of this happening. To further ensure no vapors enter the pump the cold finger can be placed in a cylinder or ice, dry ice, dry ice/acetone mix. |

![]()

Combined vacuum pump regulator and water chiller baths

|

Combined chiller vacuum pumps are available on ebay but there seems to be no way of regulating the vacuum pressure or temperature. |

![]()